professional rubber grommets manufacturer

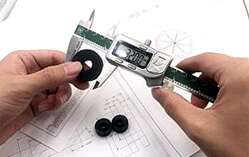

We are a professional rubber grommets manufacturer with more than 20 years experience, producing over 18,000+ kinds of rubber products for our customers. We have an experienced team who can solve various problems from design to production. For any special shaped rubber grommets, fastest 48 hours can be achieved from design prototype to production samples.

Rubber grommets

rubber grommets

Rubber grommets are a kind of accessories of the wiring equipment. There are used for wires through in the middle of holes. The purpose is to protect the wires from being cut easily by sharp plate cuttings, and at the same time, it is dustproof and waterproof. It is widely used in various fields such as electronics, electrical appliances, machinery, sports equipment, furniture, and lighting.

There are many types of rubber materials for the production of rubber grommets. Commonly used materials are Nitrile rubber, Natural rubber, Neoprene, Silicone and fluororubber. Hardness is mostly 30-60 Shore A. Customers can customize rubber grommets of different rubber materials according to the needs of their products.

General shapes of Rubber Grommets

According to the different application of rubber grommets, and the shape of the hole on the board, generally, the Rubber Grommets are commonly used in the following shapes,

- Round Grommets

- Oval Grommets

- Square Grommets

- Blind hole Grommets

- Special Shape Grommets

Physical Properties Of Rubber Grommets

| Name | Tmperature Range | Tensile Stregth | Elongation at the Break | Rebound Resilience | Tear Strength | Abrasion Resistance |

|---|---|---|---|---|---|---|

| Natural Rubber | -70 to 80 ℃ (-96 to 170℉) | Excellent | Excellent | Excellent | Excellent | Very Good |

| BUNA-N | -35 to 130℃ (-31 to 266℉) | Excellent | Very Good | Excellent | Excellent | Very Good |

| FKM | -25 to 300℃ (-13 to 572℉) | Excellent | Excellent | Excellent | Excellent | Excellent |

| Silicone | -75 to 280℃ (-103 to 536℉) | Good | Excellent | Excellent | Good | Good |

| Neoprene | -20 to 130℃ (-4 to 266℉) | Excellent | Excellent | Good | Very Good | Excellent |

| EPDM | -40 to 150℃ (-40 to 302℉) | Excellent | Very Good | Very Good | Excellent | Excellent |

Materials options of Rubber Grommets

Natural Rubber Grommets

With high tensile strength and tear strength, the natural rubber grommets are strong and hard to be cracks. It also have a good insulation properties.

Buna-N Grommets

It is the BEST material for oil resistance compared with other rubber material. For the rubber grommets which needs to be contacted with oil, it is best to use NBR. NBR has a relatively low volume resistance and is a semiconductor rubber material which having antistatic properties.

Neoprene Grommets

The neoprene rubber grommets have excellent heat resistance, ozone aging resistance and weather resistance. It is suitable for outdoor products and work under the sunlight. As the flame retardant performance of neoprene is very good, it is also recommended to use this material for high flame retardancy products.

FKM Grommets

FKM has high chemical stability and it is the best medium resistance of all elastomers. It is suitable for use it in strong acid and strong alkali environment. Moreover, fluororubber has excellent high temperature resistance and it can work at 300℃ for a long time.

Silicone Grommets

Silicone is suitable for brightly colored grommets. It is safe and environmentally friendly. It can be food contact and skin touch directly. As it does not adhere to human tissues, it has anticoagulant effect. It is also particularly suitable to made in medical products.

Any questions? Contact us for more information!

OUR Service

Free Design

Our engineers can offer custom service for making the perfect grommets. All you need is tell us your ideas.

Free Samples

We are glad to offer you Free samples for testing. Contact us for details!

High Quality Mass Production

RoHS and Reach standard certificated.ISO9001 quality management system meet to control the quality.